Our Brands

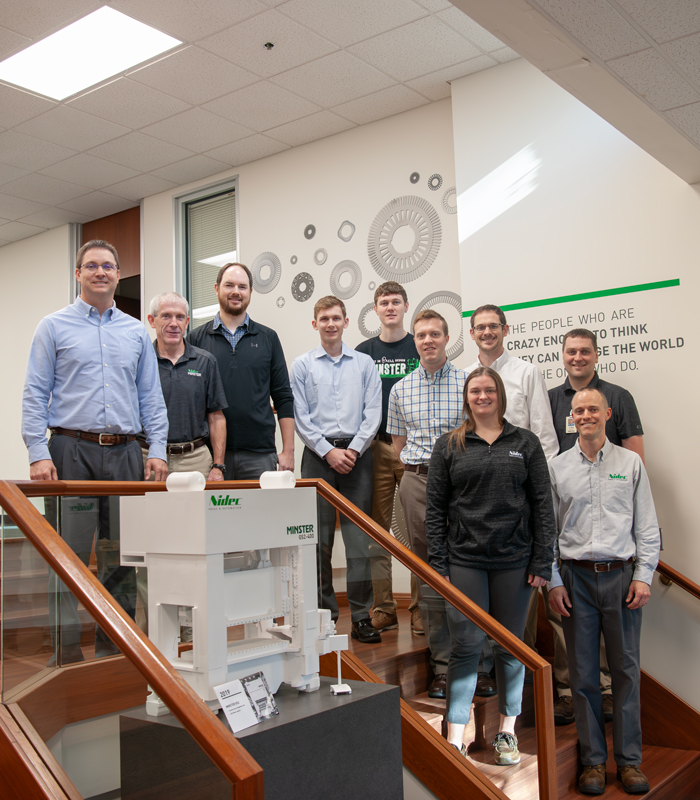

By combining the expertise, experience and resources of industry leaders in the metal forming market, Nidec Press & Automation has established a single source solution for machinery, services, and technology.

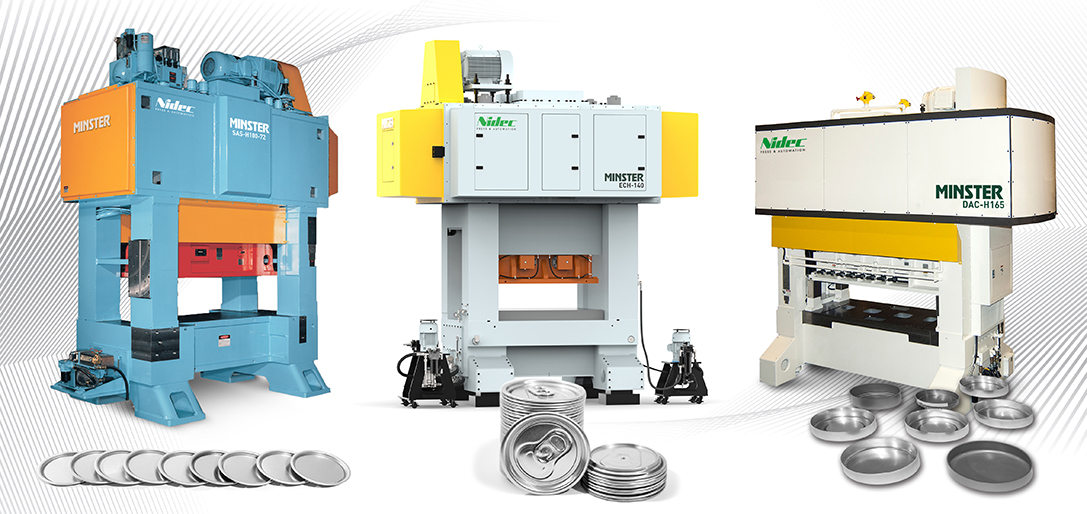

Mid-range tonnage presses and related automation equipment.

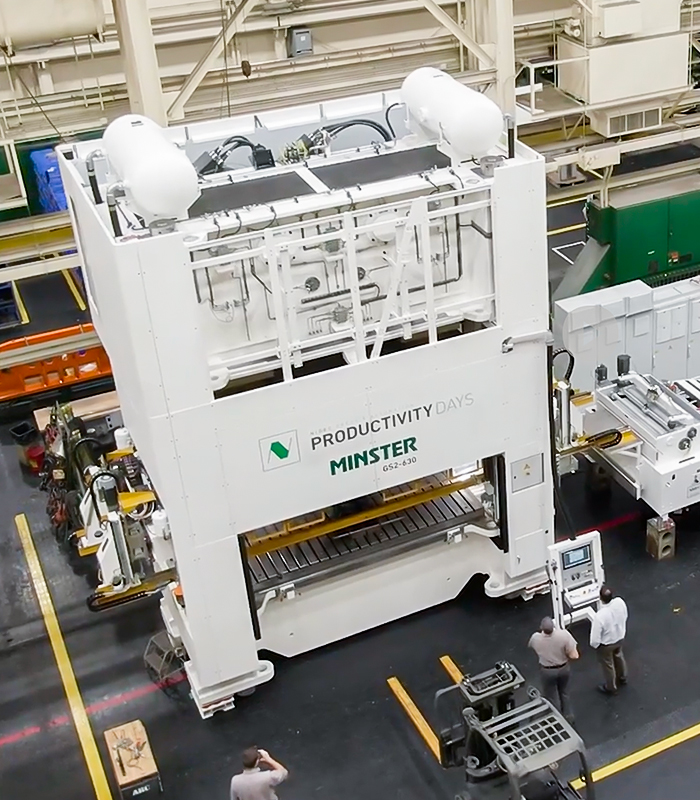

Large servo, mechanical presses, and unique transfer and material handling solutions.

Precision, high speed Kyori presses, operating at speeds of up to 3,000 strokes per minute.

High speed servo feeding systems, ideal for high speed and lamination applications.

High speed servo feeds, related automation machinery, integrated controls and press remanufacturing.

Large tonnage automation machinery, including turnkey heavy duty coil lines.

Laser blanking, premium coil processing systems, including levelers, straighteners, and stackers for Tier 1.

Press transfers and specialized automation machinery with a focus on optimizing metal stamping operations.